Research thrust I

MULTIFUNCTIONAL MATERIALS

Through in-situ experimentation and large-scale simulations, we investigate the effect of scale, arrangament and hierarchy to identify underlying mechanisms and elucidate design principles, which together with rigorous mechanics we build high-performance composite materials and nanosystems.

AREAS OF FOCUS

BIOMATERIALS

MECHANICAL METAMATERIALS

2D NANOCOMPOSITES

BIOMATERIALS

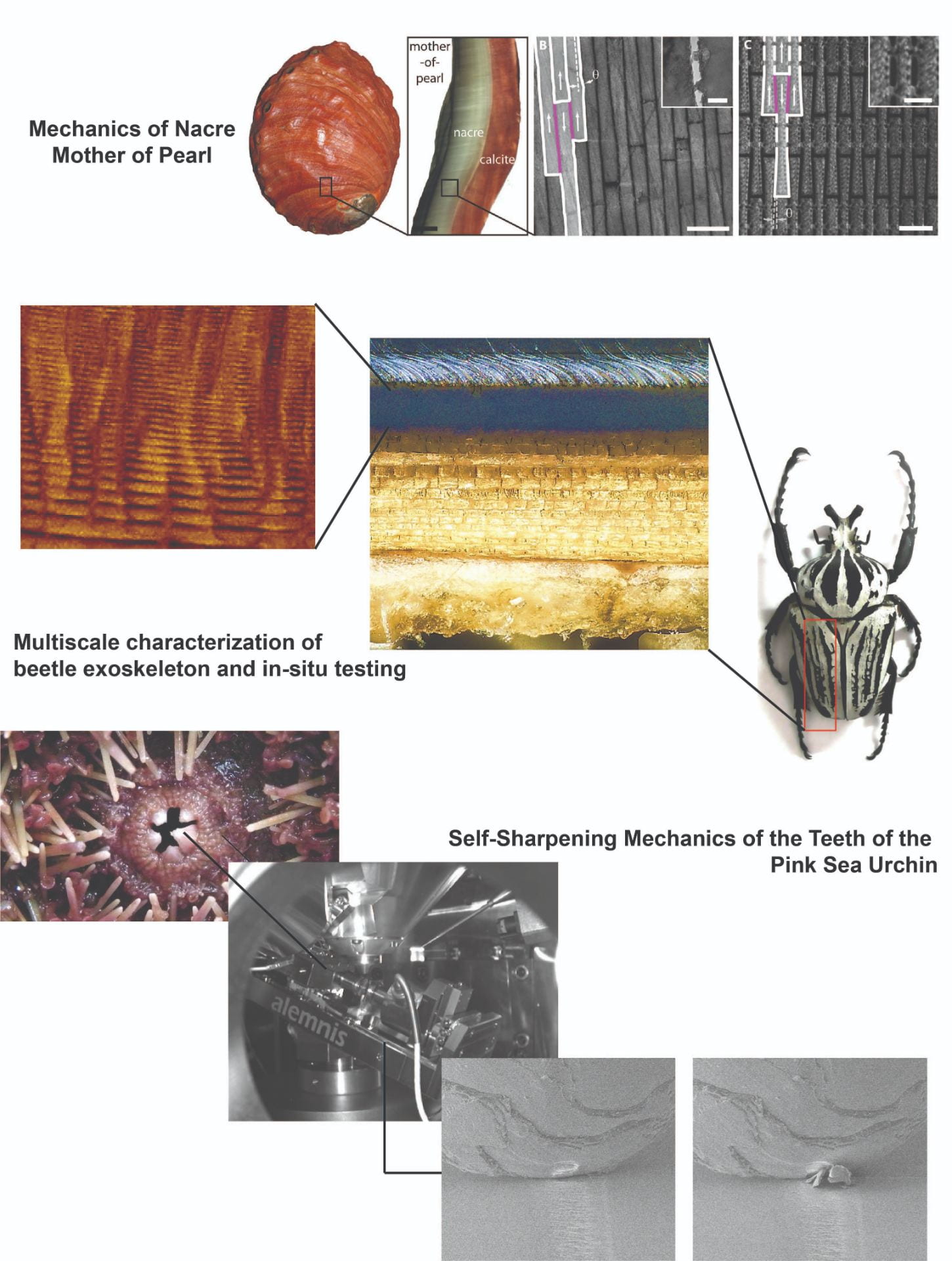

Millions of years of evolution have resulted in natural materials exhibiting unique photonic, mechanical, and thermal properties. Given the limited pool of constituents and synthesis temperatures available in Nature, natural materials exhibit a combination of hierarchical structures, heterogeneity, and exquisite organization, to achieve superior mechanical performance.

The Micro and Nanomechanics Group has a long tradition of not only unravelling the mechanics of natural materials, but also in extracting design rules and translating them into synthetic materials produced by 3D printing. Ultimately, the group aims at the design of advanced composites able to withstand a combination of extreme pressures, strain rates, and temperatures.

Among research directions in biomaterials our lab has pursued are:

-

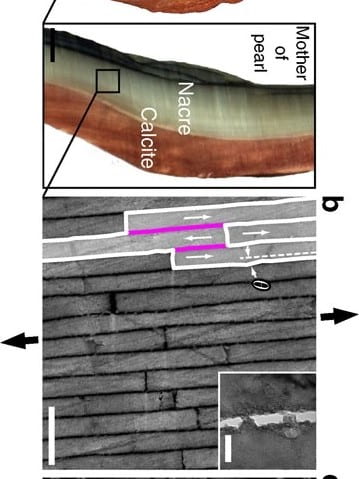

- Identification of the inelastic mechanisms responsible for the remarkable strength and toughness of Nacre, a unique biocomposite made of mineral and polymeric phases arranged in a brick-and-mortar structure. We showed that a composite, 95% ceramic and 5% polymer, achieves the toughness of aluminum. This was achieved via a unique combination of multiscale experimental techniques, using TEM, SEM, AFM, nanoindentation, and microtesters, which revealed that tablet sliding and transverse expansion (negative Poisson’s ratio) in the direction perpendicular to the tablet planes was responsible for the material toughness. Leveraging on these findings, the group devised design rules and demonstrated similar mechanisms in synthetic materials made by 3D printing.

- Characterization of the Bouligand microstructure found in the elytra of beetles. Using rigorous contact mechanics calculations and AFM nanoscale experiments, precise determination of elastic constants and geometric parameters of the helicoidal fiber arrangement was achieved for the first time.

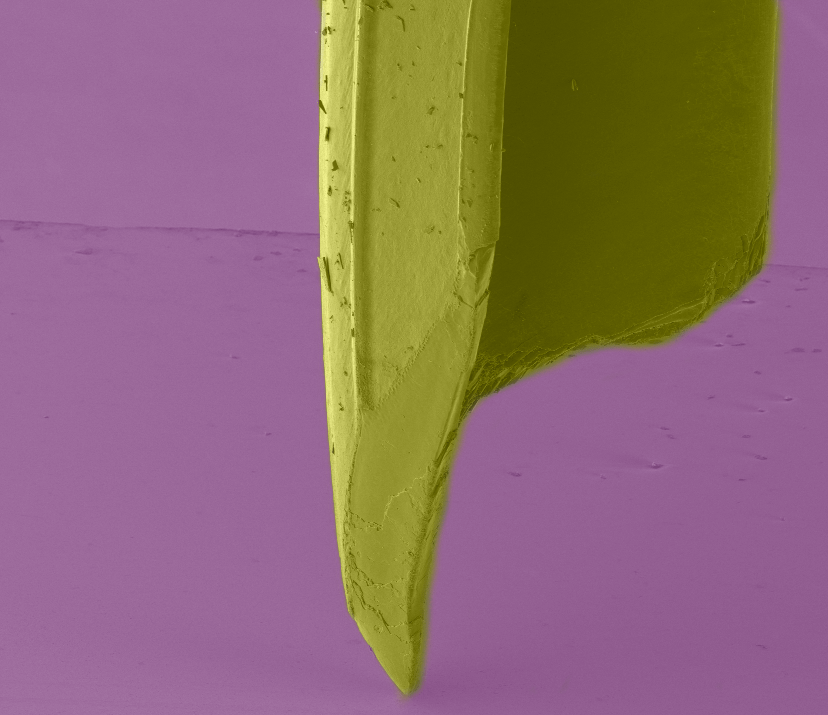

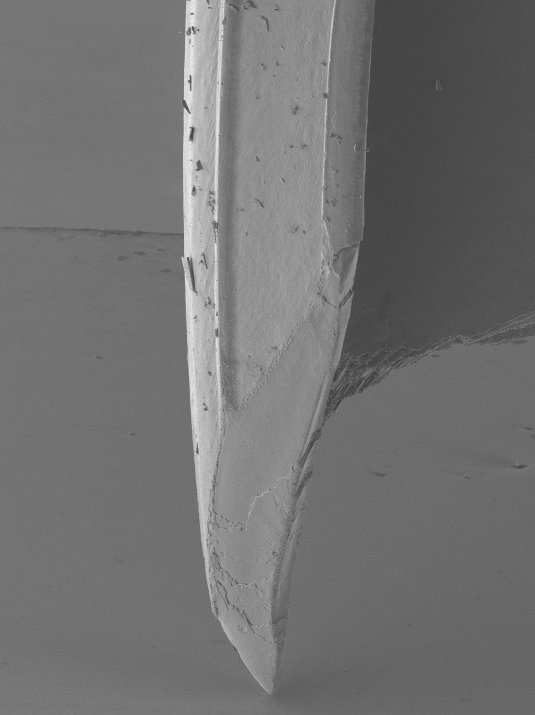

- Direct observation of the hypothesized self-sharpening phenomenon in the teeth of the pink sea-urchin. The development of a novel in-situ SEM scratch test enabled the first observation and quantification for teeth sharpness preservation, a phenomenon relevant to the design of machine tools, tunnel boring, and other material removal processes.

*Movie: In-situ SEM Scratch test

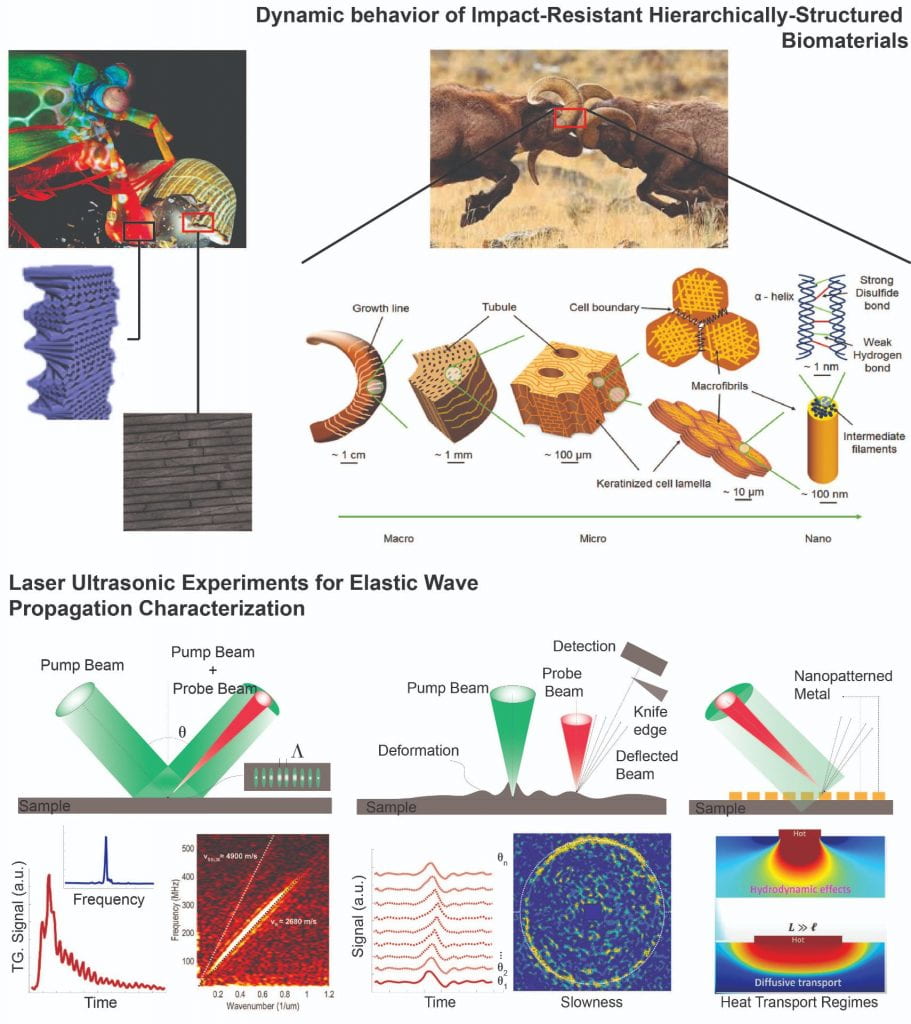

Currently, we are investigating the dynamic behavior of biomaterials, particularly the presence of bio-phononic effects. While the incredible impact resistance and vibration absorption properties in some biological specimens (e.g., mantis shrimp, bighorn sheep, etc.) is well-known, most investigations have been confined to the static regime. Borrowing the concepts of phonons from the realm of wave-metamaterials, we envision the multiscale hierarchical structures of biomaterials, coupled to their exquisite use of multiphase materials, makes them prime candidates to exhibit interesting linear and non-linear elastic wave effects.

To such end, we are employing a suite of non-contact, non-destructive laser ultrasonic experimental techniques (i.e., Transient Grating Spectroscopy, Photodeflection, Asynchronous Optical Sampling, and Interferometry) to generate bulk and surface elastic waves and simultaneously monitor how they propagate through the intricate structure of biomaterials. The techniques enable the study of waves travelling with frequencies in the kHz, MHz, and GHz regimes. Using advanced signal processing algorithms, we gain information on the dispersion characteristics of the material (wave number-frequency relationship), its mechanical and directional properties, and the way heat is transported.

*Movie: SAW on Nacre

Ultimately, we expect to translate acquired knowledge into advanced composites that will be able to endure stringent dynamic regimes, with improved vibration and wave filtering capabilities.

MECHANICAL METAMATERIALS

Metamaterials are synthetic materials engineered to have properties not found in naturally occurring materials. They are being designed for a broad set of applications ranging from light modulation, wearable electronic devices, microrobotics, and energy dissipation and redirection to mention just a few. Their design exploits advances in chemistry, self-assembly, and additive manufacturing to achieve many possible spatial configurations. In mechanical metamaterials, extreme and unusual mechanical properties are obtained by exploiting the motion, strain, stress, and energy of random and periodic meta-atoms. Such is the space of possibilities under this new paradigm that a rich variety of metamaterials exist, including: cellular and extremal metamaterials, mechanism-based, instability-based, and topological metamaterials.

In the Micro and Nanomechanics Lab, we have focused on two types of mechanical metamaterials inspired by the ancient Japanese artforms of paper folding (Origami) and paper cutting (Kirigami).

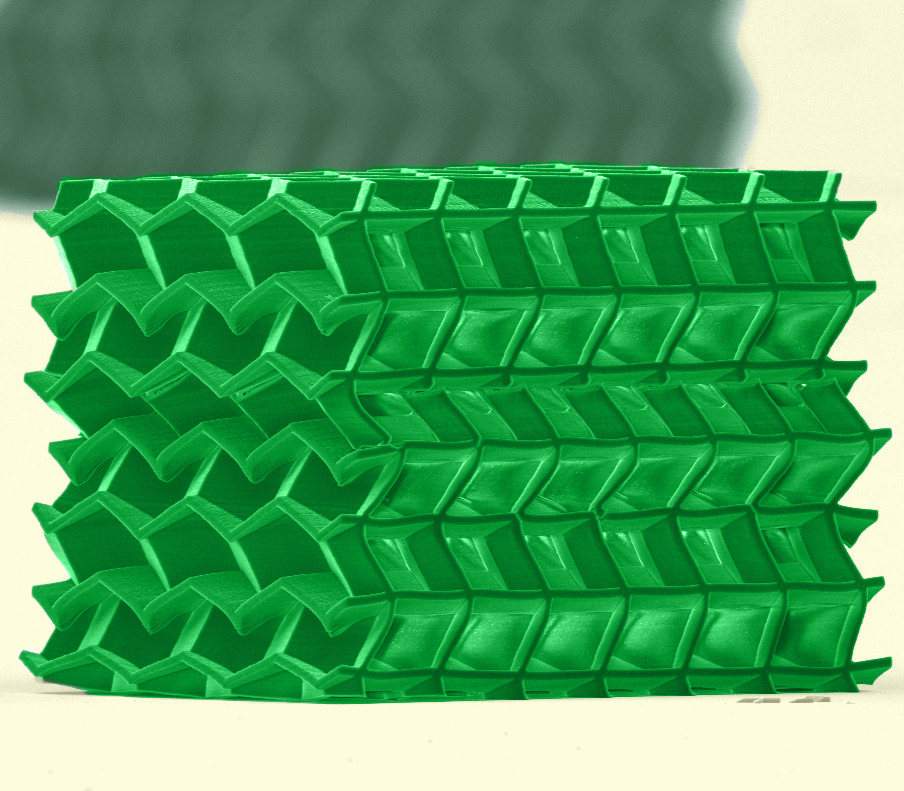

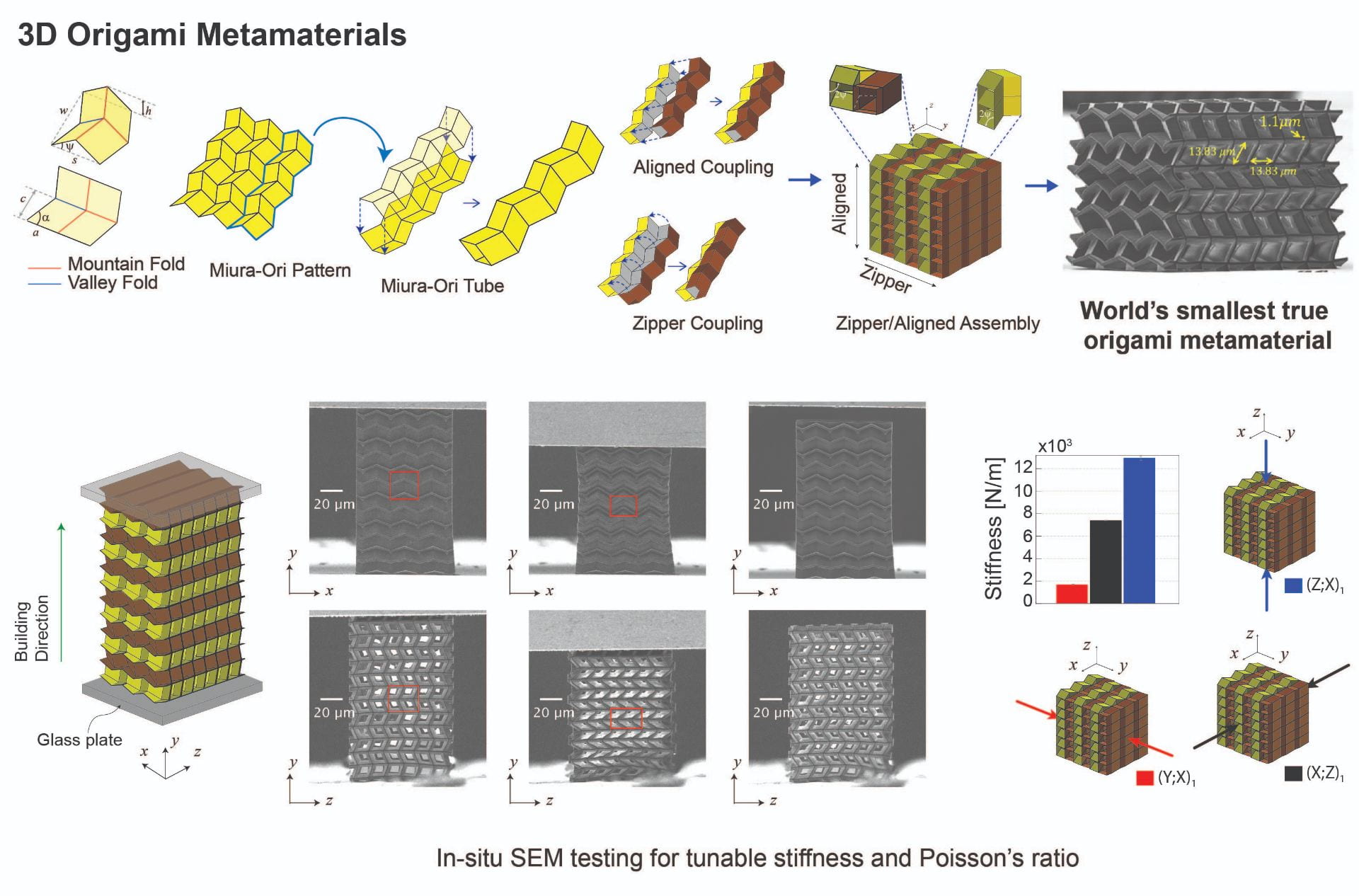

We designed a Miura-Ori cellular material, foldable in two directions and rigid in the third direction, and fabricated it using two-photon lithography. The origami structure consisted of panels with in-plane dimensions of about 10 micrometers and thicknesses of a few 100 nm! Testing under compression, in-situ a scanning electron microscope, revealed the existence of anisotropic tunable stiffness (controllable by deformation), tunable and reversible Poisson’s ratio, and elastic instabilities followed by cascading plastic collapse in the rigid direction. All these features were also predicted by analytical and finite element models.

Origami Metamaterial with Reversible Poisson’s Ratio

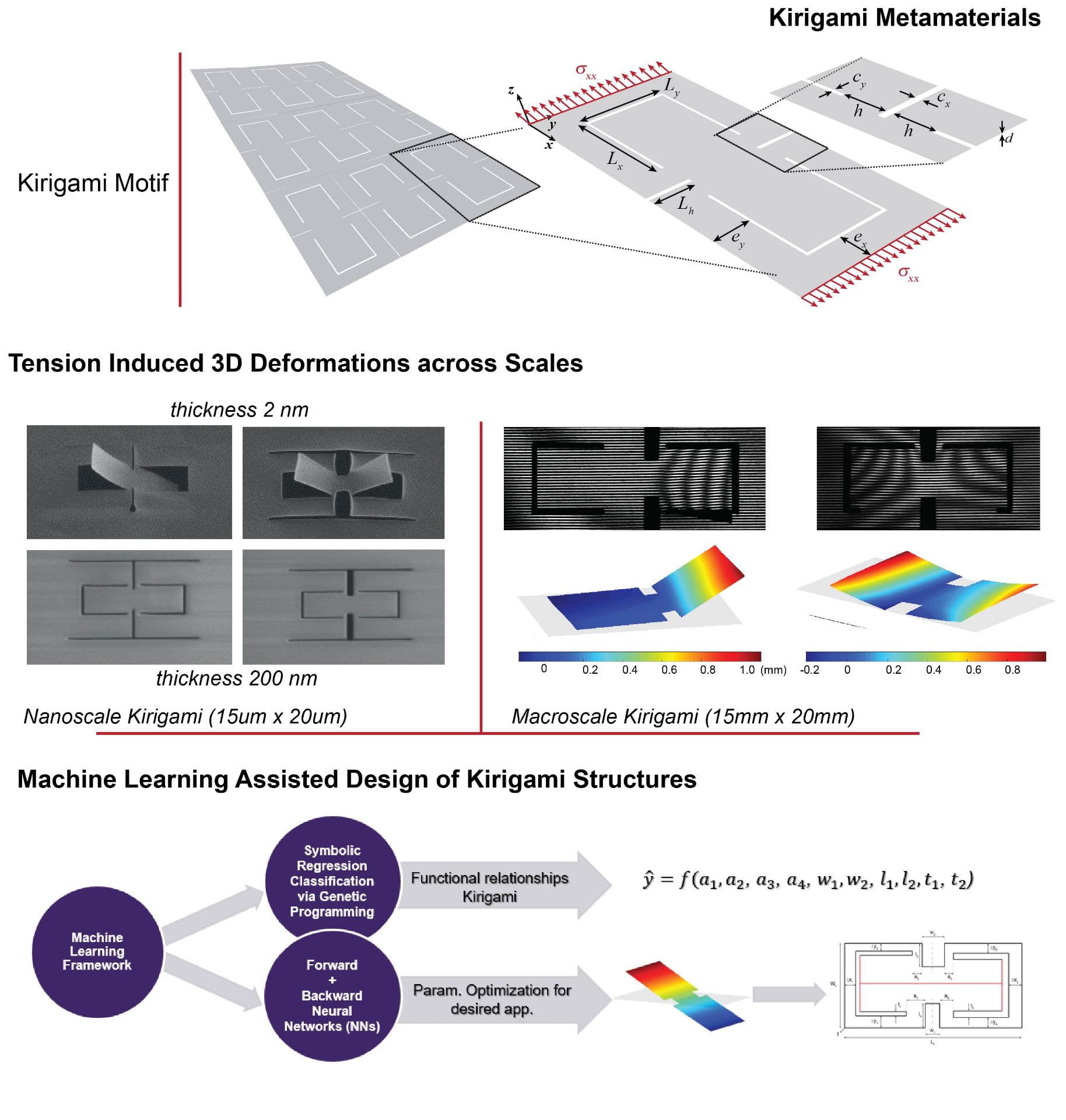

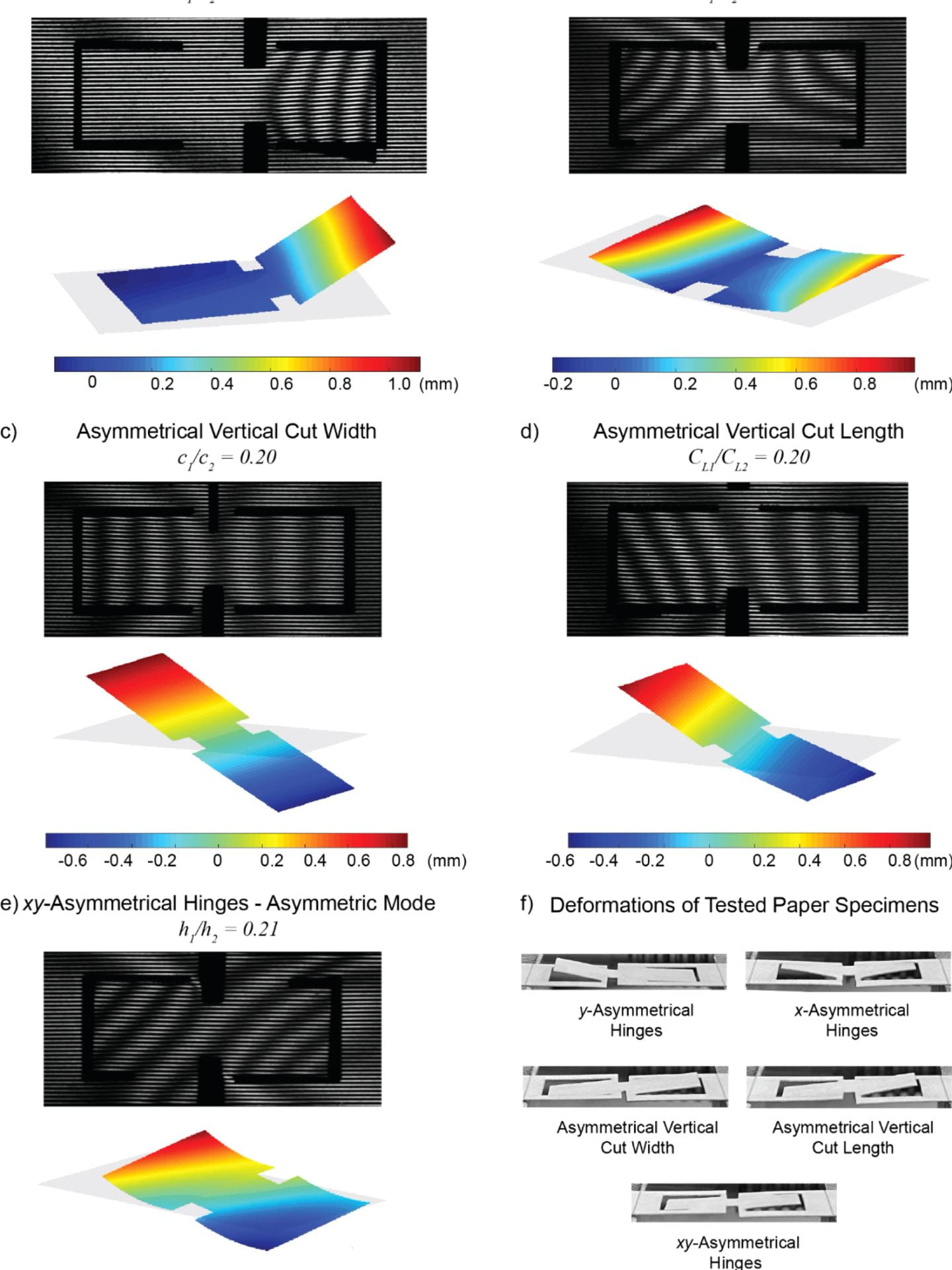

Similarly, we have investigated planar Kirigami metamaterials by focusing on a particular Kirigami cut layout (motif), which despite its simplicity has revealed a plethora of out-of-plane deformation modes because of tensile-induced instabilities. We studied these structures at the nanoscale, using silicon nitride freestanding membranes fabricated in a silicon wafer. By producing cuts with a focused ion beam (FIB), symmetric and asymmetric out-of-plane deformations resulted from instabilities caused by membrane tensile residual stresses. In a subsequent investigation, we studied a larger number of symmetric and anti-symmetric cut variations, within the same motif, and used the shadow Moire technique to experimentally verify finite element predictions. Interestingly, we observe concurrent and sequential bifurcations giving rise to complex out-of-plane shapes eliciting tilt and twist.

*Movies: FEM Analysis of Kirigami

*Movies: FEM Analysis of Kirigami

Currently, we are exploring the vast space of Kirigami motifs and 3D deformations via Machine and Deep Learning techniques. Using these methods, we are advancing surrogate models that enable the inverse design of Kirigami structures for a range of functionalities. Moreover, we are using symbolic regression, via genetic programming schemes, to predict the buckling and post-buckling behavior of these structures.

Both Kirigami and Origami metamaterials have tremendous potential in the fields of soft-robotics, programmable surfaces (e.g., tunable friction, hydro- and aerodynamic flow and thermal control, tunable thin optics), MEMS and NEMS. In the future, we are planning to investigate functional origami/kirigami structures (arrays) as well as their behavior in dynamic regimes (wave propagation, dynamic instabilities, etc.)

2D NANOCOMPOSITES

Materials Genome Initiative

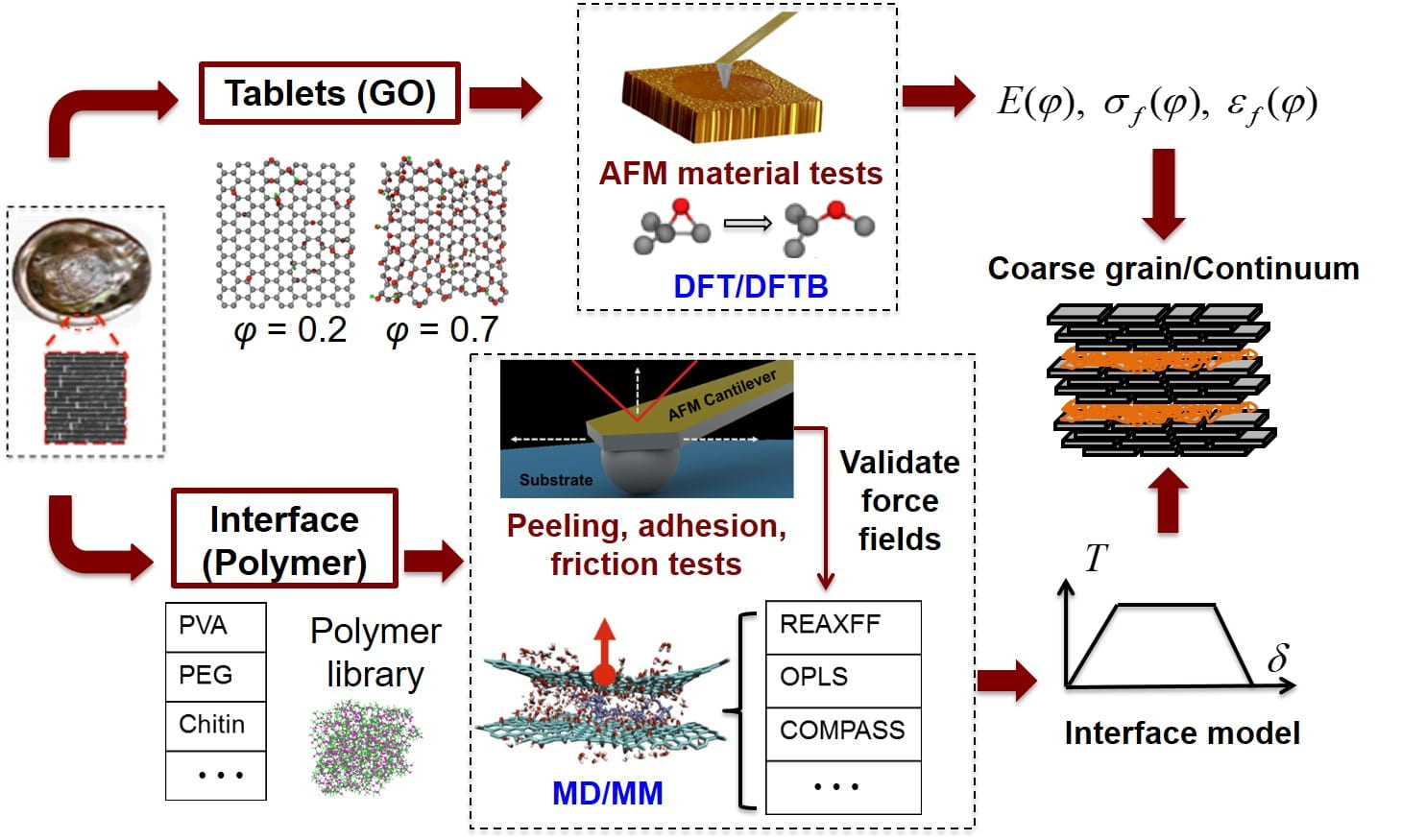

The demand for lightweight, strong, and tough materials, in transportation, space exploration, and energy applications, continues to drive the search for novel composites that can exploit advances in material synthesis and characterization. Among them, the emergence and rise of atomically thin 2D materials epitomizes nanoscale refinement, offering reinforcing constituents with unprecedented optical, electrical, and mechanical properties. When combined with intercalated polymers and metals, a plethora of new materials is envisioned. Exploration of such combinatorial problem calls for acceleration strategies, the so-called Materials Genome Initiative (MGI), that could enable identification, synthesis, and characterization of conceptualized nanocomposites system. In this respect, establishing research frameworks for assessing the predictive capabilities of computational models to screen and select promising candidates is highly needed. In the spirit of MGI, we advanced a combined experimental-computational framework with graphene oxide (GO)-polymer nacre-like nanocomposites as a case study. By employing in situ TEM and AFM experiments, we built a fundamental understanding of deformation and fracture of GO flakes, GO intralayer, and GO-polymer interfacial properties. We also assessed the predictive capabilities of atomistic simulations based on commonly used force fields. By selecting those that agree with experiments, we used atomistic simulation outputs to formulate continuum models for predicting mechanical properties of nanocomposites at larger scales. Current work involves expanding this approach to other 2D Materials-synthetic polymer systems.

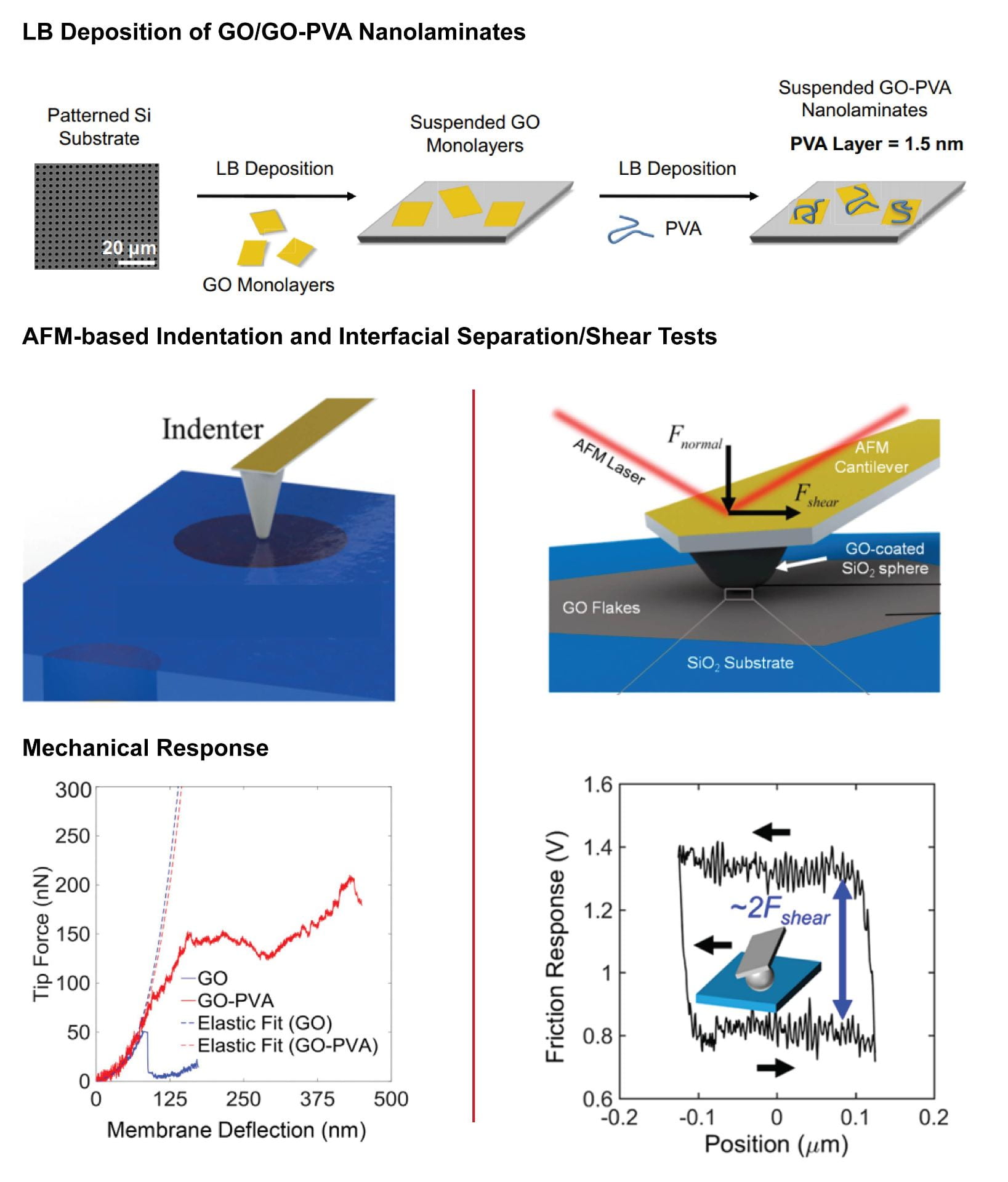

Nanoscale Experiments & Atomistic Simulations

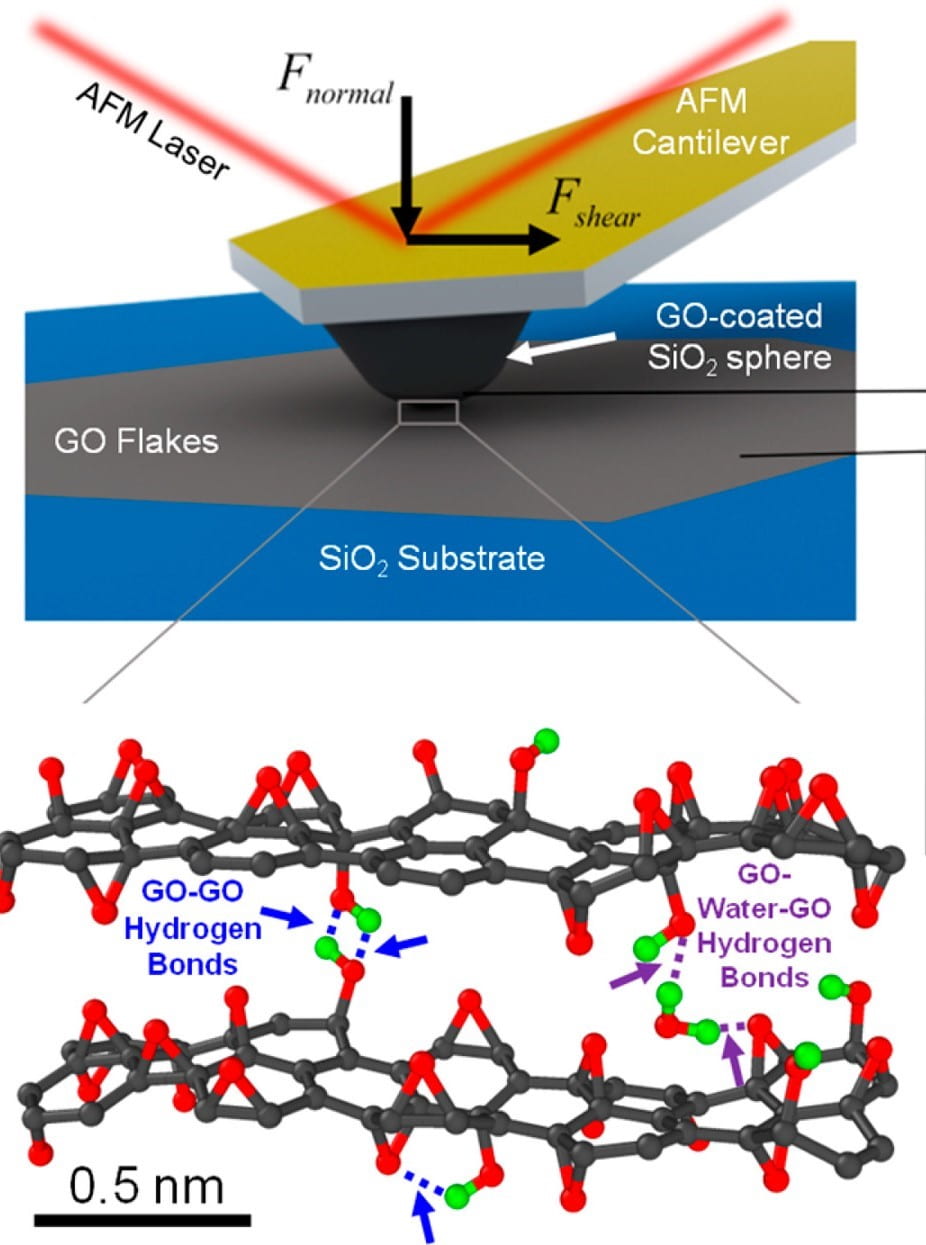

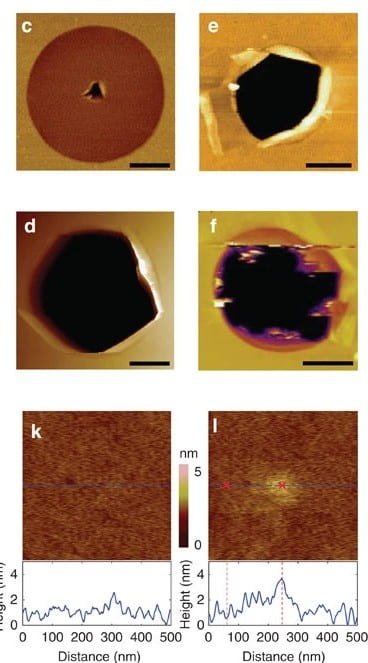

To elucidate the role of chemistry and bond type, we conduct AFM-based mechanical tests on the building blocks of GO-based nanocomposites, e.g., GO-GO interfaces and GO-polymer interfaces. We utilize Langmuir-Blodgett deposition to prepare ultrathin GO-polymer nanolaminates and monolayer GO flakes that when tested using AFM indentation and adhesion/shear tests, key nanomechanical properties such as nanolaminate rupture strength, interfacial adhesion energy, and interfacial shear strength are measured. The measured properties at the building block level enable us to elucidate the role of surface chemistry, bond type and density, polymer chain length, and water content on mechanical properties of the nanocomposites.

Also, we conduct molecular dynamics (MD) simulations to explore the governing mechanics of the atomically thin interfaces. We screen and select MD force fields with good accuracy on 2D material-based systems, e.g., ReaxFF and CHARMM, and configure simulation systems that best mimic experimental setups. Employing MD simulations, we conduct detailed analysis on interfacial chemistry (i.e., hydrogen bonding versus van der Waals interactions), interfacial hydrogen bonding, polymer, and water configurations, and correlate those data to their mechanical response. The MD simulations also enable parametric studies on various design choices in the spirit of the Materials Genome Initiative.

Currently, we are expanding our efforts to:

- Incorporate nanoscale phenomena into continuum level models to predict material functionality at the application length scale.

- Exploring 2D material-based structural composites.

*Movie: Stick-slip motion of polymer chains in GO

SELECT PUBLICATIONS

BIOMATERIALS

In situ wear study reveals role of microstructure on self-sharpening mechanism in sea urchin teeth

H.D. Espinosa*†, A. Zaheri, H. Nguyen, D. Restrepo, M. Daly, M. Frank, J. McKittrick

Matter 1(5), 2019, pp. 1246-1261

The teeth of animals play a crucial role in their survival, and, like other body parts, they adapted to the host’s habitat to maximize their functionality. Superior performance in the sea urchin dentition system was hypothesized to emerge from sharpness preservation during the organism’s life span. In this work, a novel in situ scanning electron microscopy experimental methodology was employed to visualize a mechanism for sharpness preservation and to quantify conditions for its activation. Nonlinear finite-element modeling…

AFM identification of beetle exocuticle: Bouligand structure and nanofiber anisotropic elastic properties

R. Yang, A. Zaheri, W. Gao, C. Hayashi, H.D. Espinosa†

Advanced Functional Materials 27(6), 2017, pp. 1603993

One of the common architectures in natural materials is the helicoidal (Bouligand) structure, where fiber layers twist around a helical screw. Despite the many studies that have shown the existence of Bouligand structures, methods for nanoscale structural characterization and identification of fiber mechanical properties remain to be developed. In this study, we used the exocuticle of Cotinis mutabilis (a beetle in the Cetoniinae) as a model material to develop a new experimental‐theoretical methodology that combines atomic force microscopy‐based….

Tablet-level origin of toughening in abalone shells and translation to synthetic composite materials

H.D. Espinosa†, A.L. Juster, F.J. Latourte, O.Y. Loh, D. Gregoire, P.D. Zavattieri

Nature Communications 2(1), 2011, pp. 1-9

Nacre, the iridescent material in seashells, is one of many natural materials employing hierarchical structures to achieve high strength and toughness from relatively weak constituents. Incorporating these structures into composites is appealing as conventional engineering materials often sacrifice strength to improve toughness. Researchers hypothesize that nacre’s toughness originates within its brick-and-mortar-like microstructure. Under loading, bricks slide relative to each other, propagating inelastic deformation…

On the mechanics of mother-of-pearl: a key feature in the material hierarchical structure

F. Barthelat†, H. Tang, P.D. Zavattieri, C-M. Li, H.D. Espinosa†

Journal of the Mechanics and Physics of Solids 55(2), 2007, pp. 306-337

Mother-of-pearl, also known as nacre, is the iridescent material which forms the inner layer of seashells from gastropods and bivalves. It is mostly made of microscopic ceramic tablets densely packed and bonded together by a thin layer of biopolymer. The hierarchical microstructure of this biological material is the result of millions of years of evolution, and it is so well organized that its strength and toughness are far superior to the ceramic it is made of. In this work the structure of nacre is described over several length scales…

METAMATERIALS

Kirigami Engineering—Nanoscale Structures Exhibiting a Range of Controllable 3D Configurations

X. Zhang, L. Medina, H. Cai, V. Aksyuk, H.D. Espinosa†, D. Lopez†

Advanced Materials 33(5), 2021, pp. 2005275

Kirigami structures provide a promising approach to transform flat films into 3D complex structures that are difficult to achieve by conventional fabrication approaches. By designing the cutting geometry, it is shown that distinct buckling-induced out-of-plane configurations can be obtained, separated by a sharp transition characterized by a critical geometric dimension of the structures. In situ electron microscopy experiments reveal the effect of the ratio between the in-plane cut size and film thickness on out-of-plane configurations. Moreover, geometrically nonlinear finite element analyses (FEA) accurately predict the out-of-plane modes…

Programmable 3D structures via Kirigami engineering and controlled stretching

N.A. Alderete, L. Medina, L. Lamberti, C. Sciammarella, H.D. Espinosa†

Extreme Mechanics Letters 43, 2021, pp. 101146

Kirigami with a variety of cut patterns have been recently investigated as means to transform 2D surfaces into 3D structures, offering a number of functionalities. In this work, we show that a single Kirigami motif, defining two inner panels connected by hinges, can generate a rich variety of out-of-plane symmetric and asymmetric deformation modes. The out-of-plane responses, caused by local instabilities when a far field tensile load is applied, manifest themselves at the inner plates, exhibiting a combination of one- and two-dimensional rotations (tilt and twist), effectively morphing the planar geometries into complex 3D surfaces…

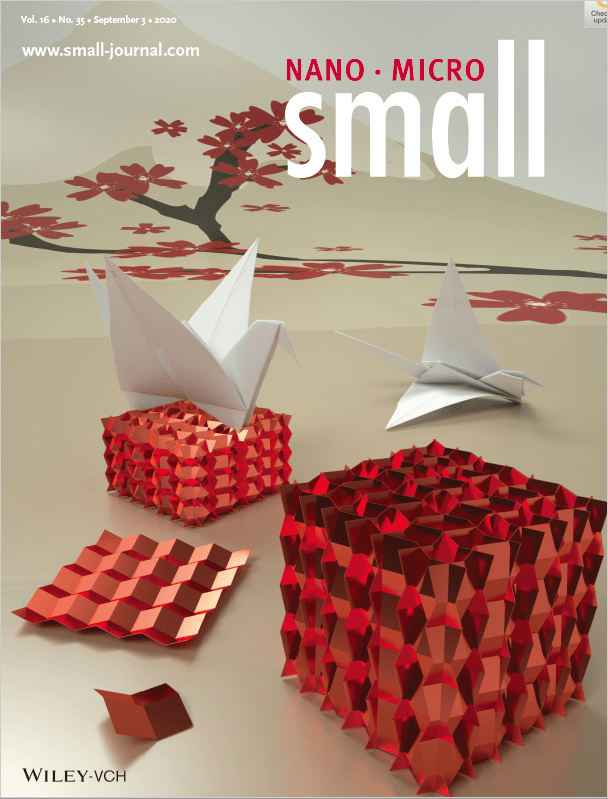

Folding at the Microscale: Enabling Multifunctional 3D Origami‐Architected Metamaterials

Z. Lin*, L.S. Novelino*, H. Wei*, N.A. Alderete*, G.H. Paulino†, H.D. Espinosa†, S. Krishnaswamy†

Small 16(35), 2020, pp. 2002229

Mechanical metamaterials inspired by the Japanese art of paper folding have gained considerable attention because of their potential to yield deployable and highly tunable assemblies. The inherent foldability of origami structures enlarges the material design space with remarkable properties such as auxeticity and high deformation recoverability and deployability, the latter being key in applications where spatial constraints are pivotal. This work integrates the results of the design, 3D direct laser writing fabrication, and in situ scanning electron microscopic mechanical…

2D NANOCOMPOSITES

Nanoscale toughening of ultrathin graphene oxide-polymer composites: mechano-chemical insights into hydrogen-bonding/van der Waals interactions, polymer chain alignment, and steric parameters

X. Zhang*, H. Nguyen*, M. Daly, S.B. T. Nguyen†, Horacio D Espinosa†

Nanoscale 11, 2019, pp. 12305-12316

This paper describes a systematic study on the nanoscale toughening of monolayer graphene oxide (GO) by an ultra-thin polymer adlayer, which impedes the propagation of cracks during intraplanar fracture. Using molecular dynamics simulations, the crack-bridging capabilities of a library of five hydrogen-bonding-capable polymers are explored against an epoxide-rich GO substrate. The best crack-bridging effect is found in polymers with functional groups…

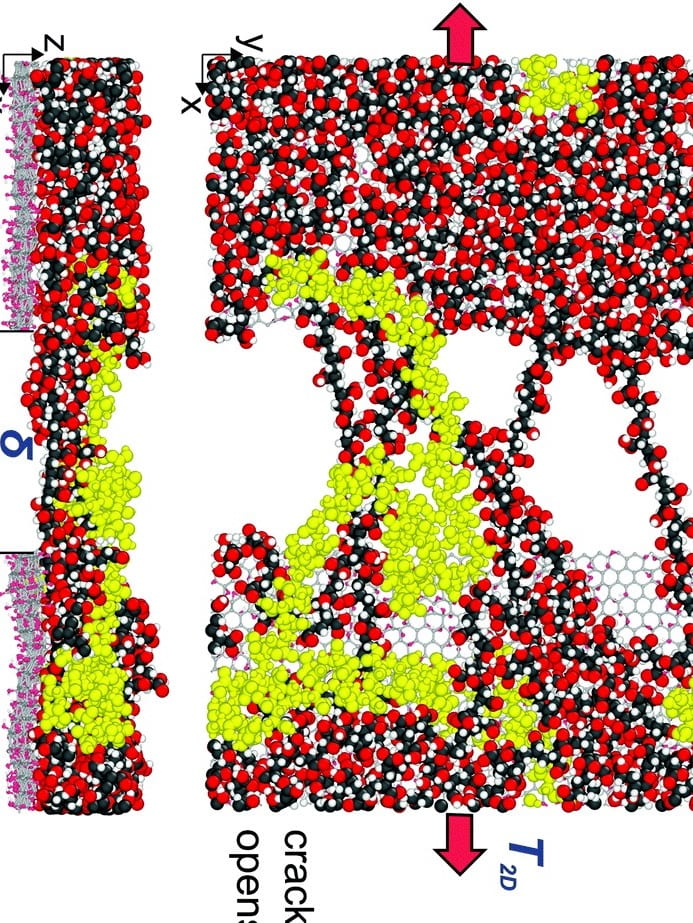

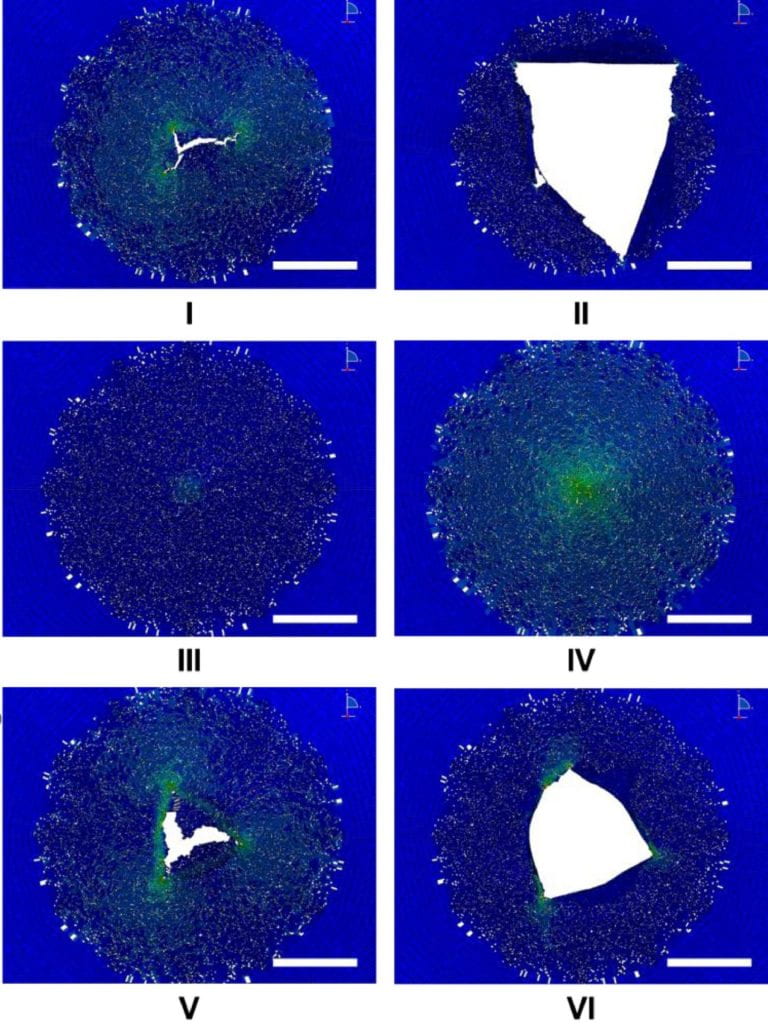

Atomically thin polymer layer enhances toughness of graphene oxide monolayers

R.A. Soler-Crespo, L. Mao, J. Wen, H.T. Nguyen, X. Zhang, X. Wei, J. Huang†, S.B.T. Nguyen†, H.D. Espinosa†

Matter 1(2), 2019, pp. 369-388

Two-dimensional (2D) materials with unconventional properties have emerged as promising candidates for addressing societal needs for advanced electronic devices and strong lightweight composites. However, their intrinsic brittle behavior and the associated risk for catastrophic failure have thus far limited their adoption. Here, we demonstrate a strategy for extrinsically toughening these materials through engineering the surface chemistry of a graphene oxide ultrathin polymer model system. Our combined experimental…

The role of water in mediating interfacial adhesion and shear strength in graphene oxide

R.A. Soler-Crespo, W. Gao, L. Mao, H.T. Nguyen, M.R. Roenbeck, J.T. Paci, J. Huang†, S.B.T. Nguyen†, H.D. Espinosa†

ACS Nano 12(6), 2018, pp. 6089-6099

Graphene oxide (GO), whose highly tunable surface chemistry enables the formation of strong interfacial hydrogen-bond networks, has garnered increasing interest in the design of devices that operate in the presence of water. For instance, previous studies have suggested that controlling GO’s surface chemistry leads to enhancements in interfacial shear strength, allowing engineers to manage deformation pathways and control failure mechanisms…

Formulation and validation of a reduced order model of 2D materials exhibiting a two-phase microstructure as applied to graphene oxide

I. Benedetti*, H. Nguyen*, R.A. Soler-Crespo*, W. Gao, L. Mao, A. Ghasemi, J. Wen, S.B. Nguyen, H.D. Espinosa†

Journal of the Mechanics and Physics of Solids 112, 2018, pp. 66-88

Novel 2D materials, e.g., graphene oxide (GO), are attractive building blocks in the design of advanced materials due to their reactive chemistry, which can enhance interfacial interactions while providing good in-plane mechanical properties. Recent studies have hypothesized that the randomly distributed two-phase microstructure of GO, which arises due to its oxidized chemistry, leads to differences in nano- vs meso‑scale mechanical responses…

Plasticity and ductility in graphene oxide through a mechanochemically induced damage tolerance mechanism

X. Wei, L. Mao, R.A. Soler-Crespo, J.T. Paci, J. Huang†, S.B.T. Nguyen†, H.D. Espinosa†

Nature Communications 6(1), 2015, pp. 1-9

The ability to bias chemical reaction pathways is a fundamental goal for chemists and material scientists to produce innovative materials. Recently, two-dimensional materials have emerged as potential platforms for exploring novel mechanically activated chemical reactions. Here we report a mechanochemical phenomenon in graphene oxide membranes, covalent epoxide-to-ether functional group transformations that deviate from epoxide ring-opening reactions, discovered through nanomechanical experiments and density functional-based tight binding calculations. These mechanochemical transformations in a two-dimensional system are directionally dependent, and confer pronounced plasticity and damage tolerance to graphene oxide monolayers…